- Home

- Quality Assurance

Quality Assurance

Build to Trust, Beyond Industry Standards

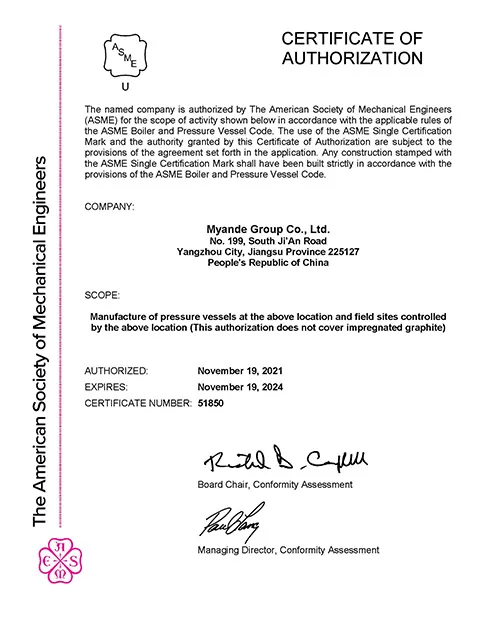

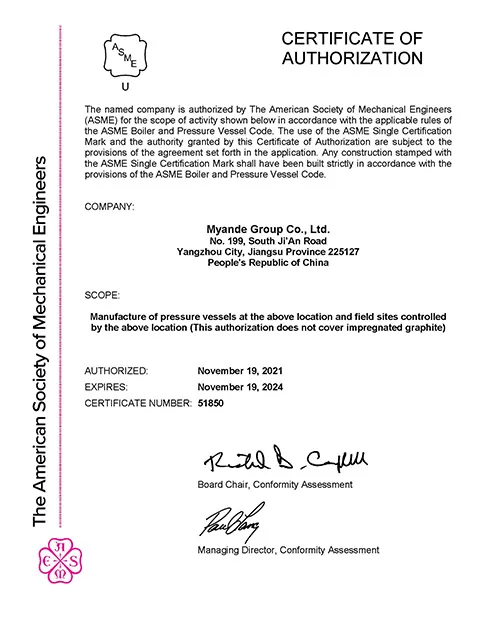

Our factory adheres to the principles of lean manufacturing and maintains strict quality standards at every stage of the process. We proudly hold international standard certifications, including ISO9001, Quality Management System Certification, ASME, CE, CUTR, and DOSH, ensuring our evaporation and crystallization equipment meets the highest global standards of safety and efficiency.

ISO9001

CE

ASME

CE

ASME

How It Works

01 Quality Materials Only

Chemical composition, mechanical properties, and dimensional analyses ensure that all raw materials, including titanium steel, duplex steel, stainless steel, and explosion-bonded titanium-steel plates, adhere to high-quality standards. Sourced from leading brands, these materials guarantee both consistency and reliability.

02 Conduct Process Testing

• Cylinder Roundness and Dimensional Inspection: Verifies that all cylinders are crafted with exact roundness and dimensions.

• Weld Radiographic Testing: Uses X-ray technology to ensure all welds are flawless and structurally secure.

• Piping and Shell Pressure Testing: Tests piping and shells for their ability to withstand specified pressures without leakage, adhering to safety standards.

• Weld Radiographic Testing: Uses X-ray technology to ensure all welds are flawless and structurally secure.

• Piping and Shell Pressure Testing: Tests piping and shells for their ability to withstand specified pressures without leakage, adhering to safety standards.

03 Pre-Shipment Inspection

Before shipment, we conduct detailed inspections to verify product dimensions, finishing, and packaging. We also ensure that all necessary documents are complete. These steps confirm that our products meet all quality standards and are ready for safe transit.

04 On-Site Validation

• Process Verification: Ensures correct installation of pipelines, valves, and gauges, and performs pressure and water tests along with steam line checks.

• Equipment Check: Confirms proper installation and functioning of all machines through individual and linked operational tests.

• Electrical Inspection: Checks the correct installation and operation of instruments and system interlocks, and conducts start-stop tests to verify electrical reliability.

• Testing with Material: Uses actual materials to validate that the process can handle the intended workload and meet production quality standards.

• Equipment Check: Confirms proper installation and functioning of all machines through individual and linked operational tests.

• Electrical Inspection: Checks the correct installation and operation of instruments and system interlocks, and conducts start-stop tests to verify electrical reliability.

• Testing with Material: Uses actual materials to validate that the process can handle the intended workload and meet production quality standards.

Structural Pillars of Our Test Accuracy

Water Quality Testing Lab

Our dedicated laboratory rigorously evaluates key metrics such as evaporation state and boiling point, delivering rapid and accurate test results to ensure optimal quality.

Well-Equipped Facilities

With over 400 advanced machines and specialized titanium steel welding techniques, our manufacturing system expertly handles detailed testing and processing.

Collaborative Partnerships

Partnering with reputable third-party inspection agencies, we conduct thorough quality checks, providing additional assurance of our products’ compliance with stringent standards.

Proven Experience

Our seasoned team, backed by over 20 years of expertise in fabricating evaporation and crystallization equipment, offers robust quality inspection support for your projects.