Forced Circulation Evaporator

- Home

- Evaporation Crystallization Equipment

- Forced Circulation Evaporator

Working Principle

Highlight Features of Forced Circulation Evaporator

Reduced Scaling

Easy Maintenance

High Flow Capacity

High Heat Exchange Efficiency

Automatic Control

Evaporation and Crystallization for Various Industries

Efficient Manufacturing

A self-owned manufacturing base of 130,000㎡, equipped with advanced equipment and automation systems.

Full Lifecycle Solutions

Comprehensive solutions covering design, civil engineering, automation, R&D, production, delivery, commissioning, and after-sales support.

Technical Team Support

400+ engineers with 5+ years of experience providing expertise in process engineering, civil design, and automation control systems.

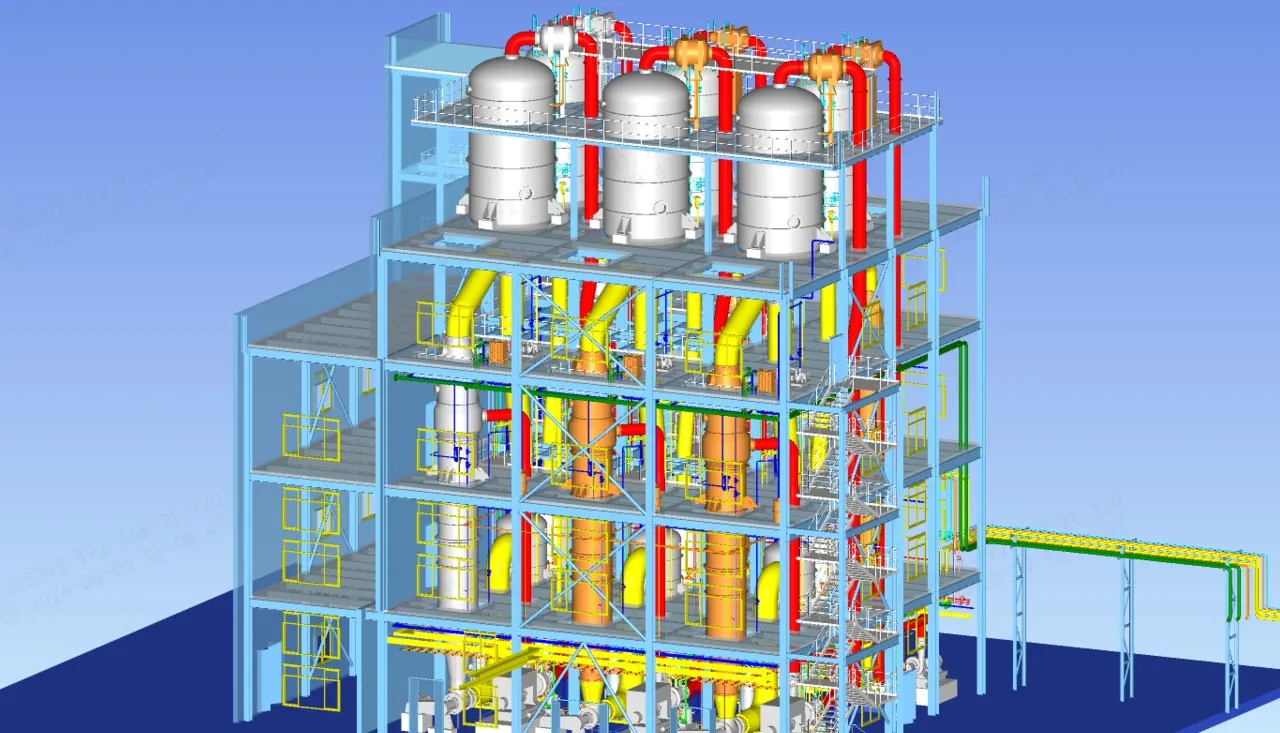

Custom Design

Providing comprehensive project planning, process design, 3D design, civil engineering design to meet specific project requirements.

After-Sales Service

Free repairs and parts replacement within an 18-month warranty, with timely technical and localized support from our overseas team.

Process Optimization

Employs low-temperature MVR evaporation, flash evaporation, and cooling crystallization to optimize energy efficiency and ensure high-quality crystals.