Imagine this: Your production line is facing a bottleneck, your waste disposal costs are skyrocketing, and valuable products are being lost in the process. The frustration of dealing with inefficient systems that can’t keep up with your production needs is all too real. But what if there was a solution that could streamline your processes, recover valuable products, and significantly reduce waste? Enter evaporation systems – the unsung heroes in various industries that offer unmatched efficiency and productivity.

Industries and Applications of Evaporation Systems

Evaporation systems are versatile tools used across a wide range of industries for purposes such as concentration, waste reduction, and product recovery. Here’s a closer look at where and how these systems are utilized:

1. Chemical Production: In the chemical industry, evaporators are essential for concentrating chemical solutions, recovering solvents, and processing waste streams. These systems help in the efficient separation and purification of chemical compounds, thereby enhancing the overall productivity of chemical manufacturing processes.

2. Food and Beverage: The food industry relies heavily on evaporators to concentrate fruit and vegetable juices, milk, coffee extracts, and in the production of condensed milk, milk powder, and dried cheese powder. By removing water from these products, evaporators help in preserving their flavor and nutritional value while extending their shelf life.

3. Pharmaceutical Production: In pharmaceutical manufacturing, evaporators are used for product recovery from waste streams and in various processes such as the concentration of active pharmaceutical ingredients (APIs) and intermediates. This ensures that the final products meet the required purity and potency standards.

4. Agricultural Chemical Production: Evaporation systems are employed in the production and processing of agricultural chemicals. They help in concentrating solutions of fertilizers, pesticides, and other agrochemicals, thereby reducing storage and transportation costs.

5. Pulp and Paper: The pulp and paper industry utilizes evaporation for chemical recovery and waste concentration. Evaporators play a crucial role in recovering valuable chemicals from black liquor, a byproduct of the pulping process, which can then be reused in the production cycle.

6. Oil and Gas: In the oil and gas sector, evaporators are used for wastewater treatment and brine concentration. These systems help in managing the large volumes of water produced during oil extraction and refining, ensuring compliance with environmental regulations and reducing disposal costs.

7. Wastewater Treatment: Many industries use evaporation systems for zero discharge facilities and to treat high concentrations of brine and processed water. Evaporators help in minimizing the environmental impact of industrial effluents by concentrating and reducing the volume of waste.

8. Mining: The mining industry employs evaporation equipment for various wastewater treatment applications. These systems are used to concentrate and purify the water used in mineral extraction processes, thereby reducing the environmental footprint of mining operations.

9. Power Plants: Evaporation systems are used in power plants for wastewater management. They help in treating the large volumes of wastewater generated during power generation, ensuring that the water can be safely discharged or reused.

10. Sugar Refining: In the sugar industry, evaporators are critical for concentrating sugar solutions during the refining process. This helps in producing high-purity sugar crystals while optimizing the use of energy and resources.

11. Salt Processing: The salt industry uses evaporation for processing and concentrating salt solutions. Evaporators help in extracting high-purity salt from brine, which is used in various industrial and consumer applications.

These industries benefit from evaporation systems due to their ability to concentrate solutions, recover valuable products, reduce waste volumes, and improve overall process efficiency. The versatility and efficiency of these systems make them indispensable in modern industrial processes.

Understanding the diverse applications of evaporation systems is just the beginning. To fully appreciate their value, it’s essential to delve into the different types of evaporators and their specific advantages. By exploring how these systems work, you can make informed decisions about which type of evaporator is best suited for your industry and process needs.

What Is the Most Common Evaporation?

The most common types of evaporators used in various industries include:

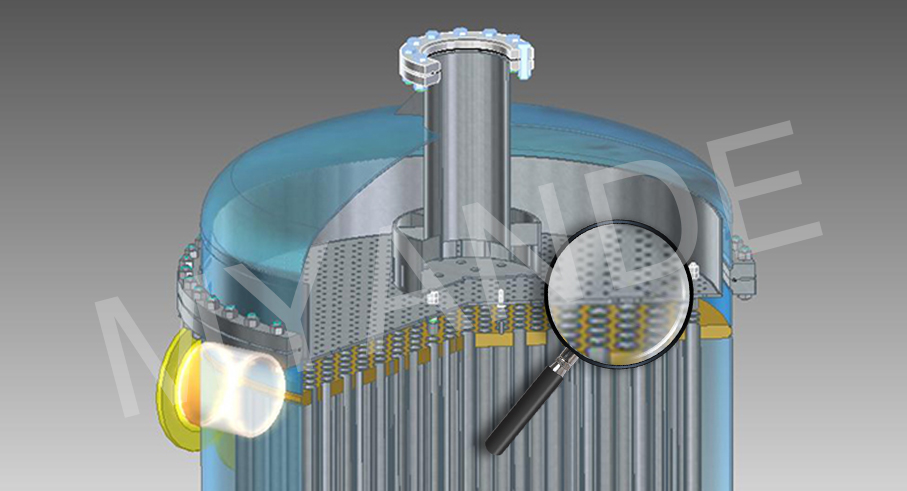

1. Falling Film Evaporators: These consist of vertical tubes where liquid flows down as a thin film, allowing for efficient heat transfer. They are commonly used for heat-sensitive products like fruit juices and milk. The thin film maximizes the surface area for evaporation while minimizing the thermal degradation of sensitive products.

2. Forced Circulation Evaporators: These use pumps to circulate the feed through heat exchangers at high velocities. They are suitable for viscous liquids, scaling solutions, or when crystallization is present. The forced circulation ensures consistent heat transfer and prevents fouling, making them ideal for challenging applications.

3. Rising Film Evaporators: Also known as long-tube vertical evaporators, these use the natural circulation of boiling liquid inside vertical tubes. They are efficient but prone to scaling. The rising film created by the boiling action enhances heat transfer, making these evaporators suitable for high-capacity applications.

4. Plate Evaporators: These use plates instead of tubes and are compact, easy to clean, and adaptable. They are widely used in the food and beverage industry. The modular design of plate evaporators allows for easy expansion and maintenance, making them a popular choice for industries with stringent hygiene requirements.

5. Natural Circulation Evaporators: These rely on density differences for liquid circulation and are suitable for a wide range of concentrations and loads. The simplicity of their design makes them cost-effective and easy to operate.

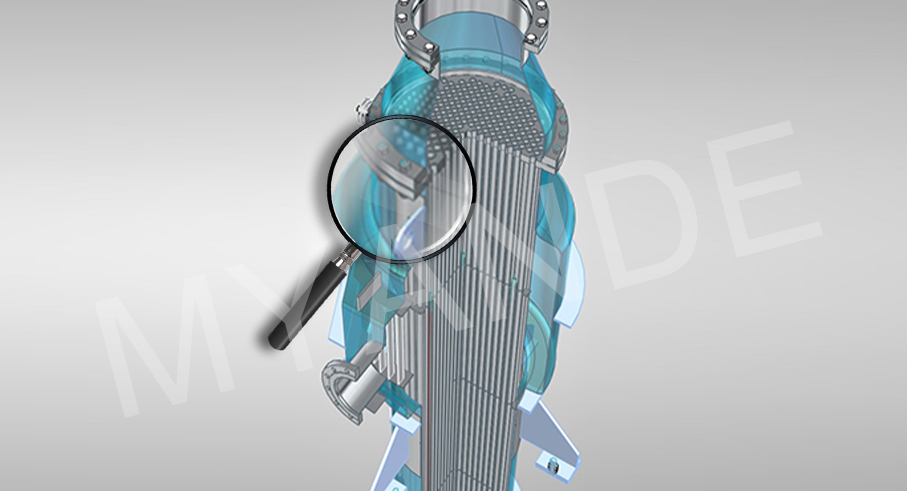

6. Multiple-Effect Evaporators: These systems use the vapor from one stage to heat the next, improving energy efficiency. They can have up to seven stages. By reusing the vapor, multiple-effect evaporators significantly reduce energy consumption, making them highly efficient for large-scale operations.

7. Mechanical Vapor Recompression (MVR) Evaporators: These compress water vapor to increase temperature and pressure, making them energy-efficient. MVR evaporators are ideal for processes that require high energy efficiency and minimal environmental impact.

8. Agitated Thin Film Evaporators: These achieve high evaporation rates and are used for specific applications. The agitation ensures uniform heat transfer and prevents fouling, making them suitable for processing highly viscous or heat-sensitive materials.

Each type of evaporator has its advantages and is chosen based on the specific requirements of the process, such as the nature of the product, desired concentration, and efficiency considerations. Understanding these differences can help you select the most appropriate evaporation system for your needs.

Conclusion

Evaporation systems are crucial in numerous industries, offering solutions for concentration, waste reduction, and product recovery. By recognizing their applications and understanding the different types of evaporators, you can leverage these systems to enhance your processes and achieve greater efficiency. Regular maintenance and selecting the right type of evaporator for your specific needs will ensure that your operations remain smooth, cost-effective, and environmentally friendly. Embrace the power of evaporation systems to transform your industrial processes and drive your business forward.